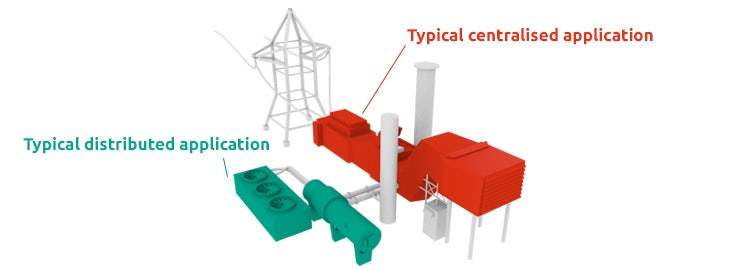

There are different system structures to facilitate machine vibration protection – one more advanced than the other. Which method is used depends on the application and the criticality of it.

1. Distributed machine protection systems

Distributed protection systems are available in all shapes and sizes, and are used to protect a wide variety of balance of plant or other (critical) equipment. A distributed system is suitable for smaller or less critical equipment, remote locations and for plants with a distributed structure. The great advantages of distributed systems are the simplicity of the systems, the lower costs, and the reduction of infrastructural requirements.

a. Vibration switches

Vibration switches can offer a basic but functional machine protection solution. A vibration switch senses vibration and will trigger a switch or an alarm when the preset values are reached. Vibration switches sense vibration as a result of, for example, imbalance, misalignment, resonance, looseness, worn-out bearings and damaged gears. Vibration switches are generally used for applications like cooling towers, fans, blowers and pumps, that require basic protection or that benefit from a simple, stand-alone system.

b. Vibration transmitters

Vibration transmitters offer a more advanced machine protection solution. Basic vibration transmitters generally have more functionality on limits and settings than vibration switches, and different interfacing options. These transmitters can be used as an interface for a control system or display.

In addition to these basic vibration transmitters, more advanced transmitter systems are available that can offer additional functions similar to centralised systems, such as multiple channels, logic options and even advanced data analysis and communication. These systems can be used as stand-alone protection or monitoring systems and even replace rack based centralised systems.